And a very deep rabbit hole it is… especially once you realize a LOT of the info out there is not at all scientific and basically this is what I did that worked for me but I don’t know why, which evolved into this is just what everyone does cause it works, with generalized explanations why.

Now before I say what I am doing, I will say it is far from what is the “normal” setup, and flies against a ton of the advice and best practices you will come across online. I also likely have the cheapest “cost” for a show of this size, as I am a major penny pincher and hate spending money when not needed.

I am using ws2812 5v RGB pixels, and some of the equivalent 5v strips. Pixels are direct from Ray Wu, and strips are btf lighting.

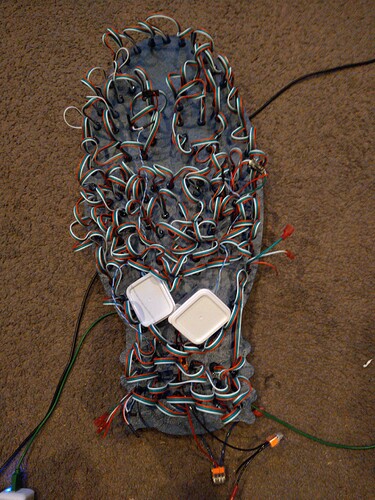

Using a single 24v power supply to run everything and avoid voltage drop issues over longer power line runs. I then use 3A buck convertors on the props to drop the voltage down to 5V. I design my stuff to be able to run all three channels at the same time at 100% brightness, though i never turn it up past 20, maybe 30 if its a foggy night, anything above that is just too bright.

That means for every 50 lights I have a buck convertor. The 2812 specs list a max draw of 20ma per channel for full brightness, of 60ma per pixel. Buck Convertors can be gotten for under .10 a piece in bulk. Power injection really comes down to 2 factors. How bright you want to be able to run your lights, and preventing discoloration from voltage drop within the string itself.

The higher the voltage and the shorter the wiring between the individual pixels the more leds you can power before needing to inject. There is really no correct answer sadly, other than as often as needed for your preferences.

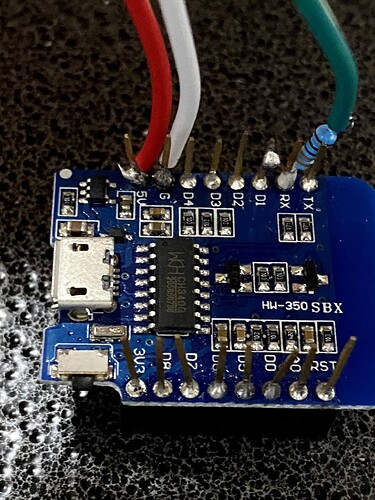

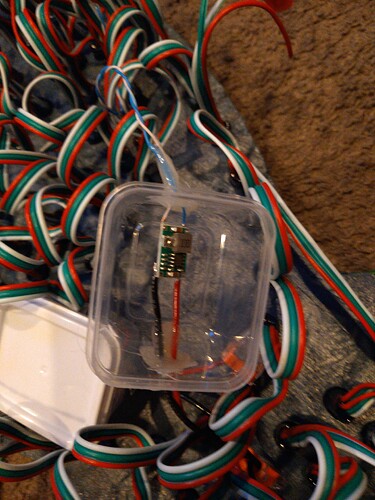

For the few controllers that are out in the yard and not protected, and the buck convertors, I am using the cheap 10 pack of mini tupperware containers from the dollar store. Melt a hole big enough for you wires on two sides (PWR+GND X 2, IN and OUT) controller goes inside, bit of hot glue to seal up around the wires and your good to go.

I am using standard covered spade connectors for all of my connections with just a touch of dialectic grease to keep them water tight.

Because I am using 24v at a lower Amperage than what would be needed if the power supply was 5v, voltage drop and load on my wires is much less of a concern.

Voltage drop for a 5v line with 48A on a 14 gauge wire over 10 feet is over 50%, leaving you with less than 2.5V at the end of that 10 foot run.

In comparison (or contrast) Voltage drop for 10A at 24V over 10 feet is only a 2%, leaving you with 23.5V at the end of 10 feet, and even at 100 feet out drop is only 22% leaving you with about 19V at the end of your run. Plenty to buck convert down to the needed 5 and drive all your lights.

Also ignore anyone telling you that you can only drive 200/400/600 leds to a port. Look up the data rate of the lights you are using and calculate the actual limits yourself. ws2812 can reliably push between 800-820 leds to a single data port at 40fps!

The best way I have found to manage wiring is using zip ties, and daisy chaining as many props/strings together as you can in terms of both power and data. Put a small fuse on each prop, that way if anything shorts out you only lose that one item and know exactly where the problem lies and only have to troubleshoot one item, rather than everything on that power/data line.

When daisy chaining strings or props ALWAYS make sure you also run a gnd parallel to the data between the end of one string/prop and the start of the next. It does not matter if they are already sharing a common ground.

Running this extra gnd with the data ensures that there are no small differentials between the data signal and ground from the last light on one string to the first of the next, and helps prevent glitches and flickering due to data corruption.

Ill stop after this final tip, as this is already a lot to take in, and may not even be of much use depending on the route you go with your setup. If you are going to be working with a lot of addressable LEDs get yourself a cheap but decent 1M bandwidth oscilloscope, it will make figuring out the cause of any potential data issue a lot easier!

![]()

![]()